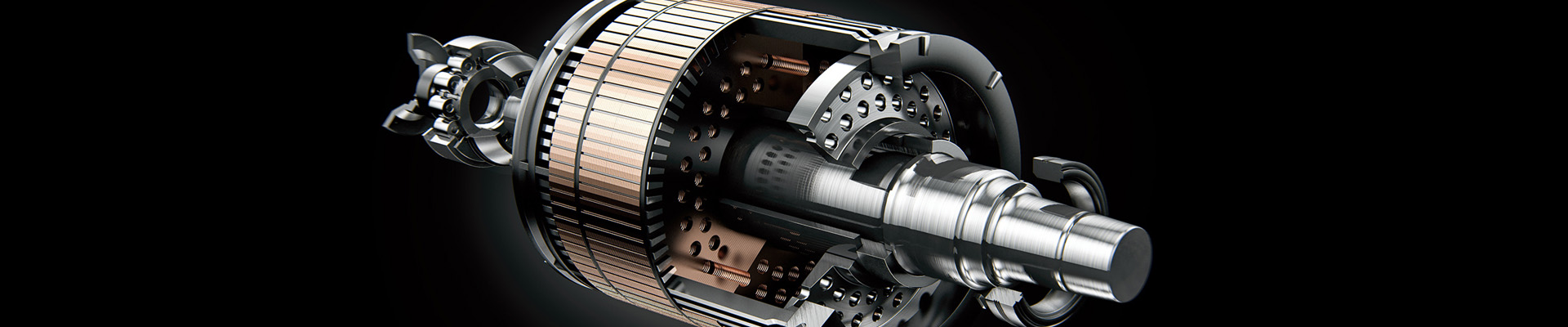

Permanent magnet synchronous motor of water jet loom

1、 Product features

The following improvements have been made in the design and material selection of rare earth permanent magnet high-efficiency three-phase synchronous motor:

a. In the structural electromagnetic design, the optimization design is made for the large starting torque of the water jet loom

b. Select high-quality permanent magnet.The advanced permanent magnet with ultra-high internal coercivity is used, which has enough internal coercivity and magnetic induction coercivity, and the working temperature is up to 120 ℃.

c. High mechanical efficiency, low loss, large starting torque, low temperature rise and reliable operation.

d. High power factor, which can reduce line loss, reduce line voltage drop and improve power supply quality.

2、 Operating environment

The motor operates normally under the following conditions:

Voltage: 380V

Ambient air temperature: - 20~40 ℃

Ambient air humidity: relative humidity of ambient air shall not exceed 85%

Altitude: no more than 1000m

Working system: S1

3、 Specifications and technical parameters

| Motor model | Rated power (kW) |

Rated current (A) |

Rated speed (r/min) |

Rated frequency (Hz) |

Rated torque (N.m) |

Efficiency (%) |

Power factor (cosφ) |

| YT-112M-4 | 2.2 | 3.6 | 1500 | 50 | 14 | 89.7 | 0.99 |

| YT-112M-4 | 2.8 | 5.3 | 1500 | 50 | 17.8 | 90.3 | 0.99 |

| YT-112M-4 | 3 | 5.3 | 1500 | 50 | 19.1 | 90.3 | 0.99 |

| YT-132M-4 | 3.7 | 6.6 | 1500 | 50 | 23.5 | 90.9 | 0.99 |

| YT-132M-4 | 4 | 6.6 | 1500 | 50 | 25.5 | 90.9 | 0.99 |

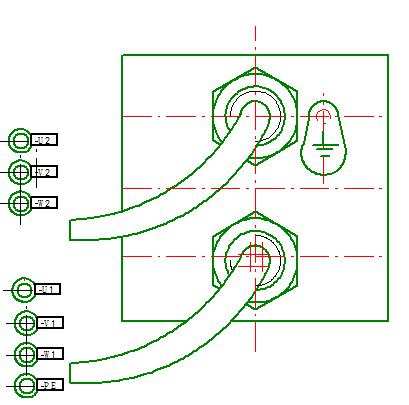

4、 Wiring method

Connection:Y、△/Y

Fig.: Wiring diagram of special motor for water jet loom

Note: When high starting torque is required, △, when the starting reaches the rated speed, it will be converted to Y operation; In general, Y can be directly started and Y can run without conversion. * Remember not to connect the wrong wire. PE ground wire is connected to the base.

Category